Warehouse racking is central to the component in economical storage management, allowing for corporations to improve Area, improve accessibility, and greatly enhance productiveness inside of their amenities. With numerous racking techniques readily available, warehouses can properly organize and shop materials dependant on their particular requires, from tiny situation to bulk products. Deciding on the proper racking technique not simply maximizes storage ability and also guarantees worker security and clean functions.

Forms of Warehouse Racking

Various styles of racking techniques are generally located in warehouses, Each and every with one of a kind pros tailor-made to unique storage demands:

Selective Pallet Racking: This is actually the commonest racking method, giving immediate entry to every single pallet. It’s extremely adaptable, which makes it well suited for warehouses using a high turnover of different goods. Selective racking maximizes accessibility, eventhough it might be not as Room-productive as other units.

Generate-In/Push-Through Racking: Designed for substantial-density storage, drive-in racking makes it possible for forklifts to receive in the racking process to keep and retrieve pallets. It’s ideal for storing large amounts of similar things in a last-in, first-out (LIFO) technique. Travel-by means of racking, Conversely, follows a primary-in, to start with-out (FIFO) program which is outstanding for stock rotation.

Cantilever Racking: Greatest suited to storing prolonged, bulky items like pipes, lumber, and steel rods, cantilever racks offer you open fronts that simplify loading and unloading. They will often be used in design and production amenities exactly where very long elements call for adaptable storage.

Push Again Racking: This system operates about the compilation of nested carts that roll alongside rails, enabling pallets remaining stored two to six deep. It’s a successful, higher-density Alternative for objects which don’t demand quick retrieval, running with a LIFO technique.

Mezzanine Racking: By introducing yet another or maybe longspan racking Sunshine Coast third degree having a warehouse, mezzanine racking properly doubles or triples readily available floor location without having expanding the developing alone. This technique is well matched for maximizing vertical Area.

Great things about Helpful Warehouse Racking

An successful racking program substantially boosts warehouse operations by optimizing space utilization, increasing accessibility, and decreasing retrieval situations. This qualified prospects to raised stock administration, as backpacks are effortlessly available and organized, which minimizes labor prices and boosts efficiency.

Racking methods also encourage safety via delivering structured and secure storage. Appropriately built racks lessen the chance of accidents, guaranteeing a great natural environment for equally workers and stock. Moreover, properly-taken care of racking devices lessen difficulties for stored merchandise, improving stock lifespan.

Selecting the Right Racking Procedure

Deciding upon the correct racking process is determined by things like available Room, stock form, turnover price, and finances. A radical evaluation of storage desires and operational flow operates very well for determining over a racking program that supports streamlined workflows and maximizes warehouse efficiency. Effectively applied, warehouse racking is unquestionably an financial commitment that pays off in Area cost savings, protection, and prolonged-time period efficiency.

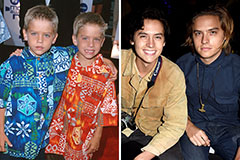

Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Patrick Renna Then & Now!

Patrick Renna Then & Now! Tonya Harding Then & Now!

Tonya Harding Then & Now! Dawn Wells Then & Now!

Dawn Wells Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now!